Poor emulsion coverage

A fairly common question when customers use our emulsion products for the first time particularly Optiva 3, 5 and 20 from our durable range.

Picture Framing

Picture framing occurs with Tikkurila materials when the film build of the paint applied around the edges is higher than the roller applied mid section.

Poor internal trim coverage using waterbased acrylics

Helmi and similar products rely heavily on surface flow and their self levelling ability. If too little product is applied to the substrate then the product will not level properly and the dried film will appear patchy.

Pinholes in drying waterbased acrylic film when spraying

If the spray film is too low due to lack of pressure, wrong tip selection or over thinning then the atomised product does not flow correctly over the substrate and gaps appear (pinholes).

Blistering in newly applied waterbased paint film

Blistering is quite common and can be caused by a number of factors including heat, cissing, poor adhesion and substrate issues

Softening of the paint film / no or slow curing

Fully water based products dry quickly but cure slowly. It is essential that the appropriate curing time for each individual product is adhered to.

Emulsion not covering properly

This is a fairly common question when customers use our emulsion products for the first time particularly Optiva 3, 5 and 20 from our durable range.

In most instances (with the exception of very bright primary colours) it is a very simple case of either not applying enough product or overworking the material across the surface. Tikkurila emulsions are highly flexible and have a tremendous ability to pull back naturally, removing the stipple effect from the wall leaving a solid non textured surface. Tikkurila products are not designed to be overworked and flattened using the roller, they are designed to pull back naturally as the product dries.

If the surface being painted is looking a little patchy after a first coat, trust the product and apply a little more paint to the surfaces with your second coat, and work the film less, you will see a stipple but trust the paint will pull the texture out. Once you get used to the product and its drying characteristics painting walls and ceilings should become much easier as less working of the film is required.

Issue: Poor hiding / Grinning

Cause: Low Film Build / Overworking

Solution: Do not overwork the product, trust it will pull back flat

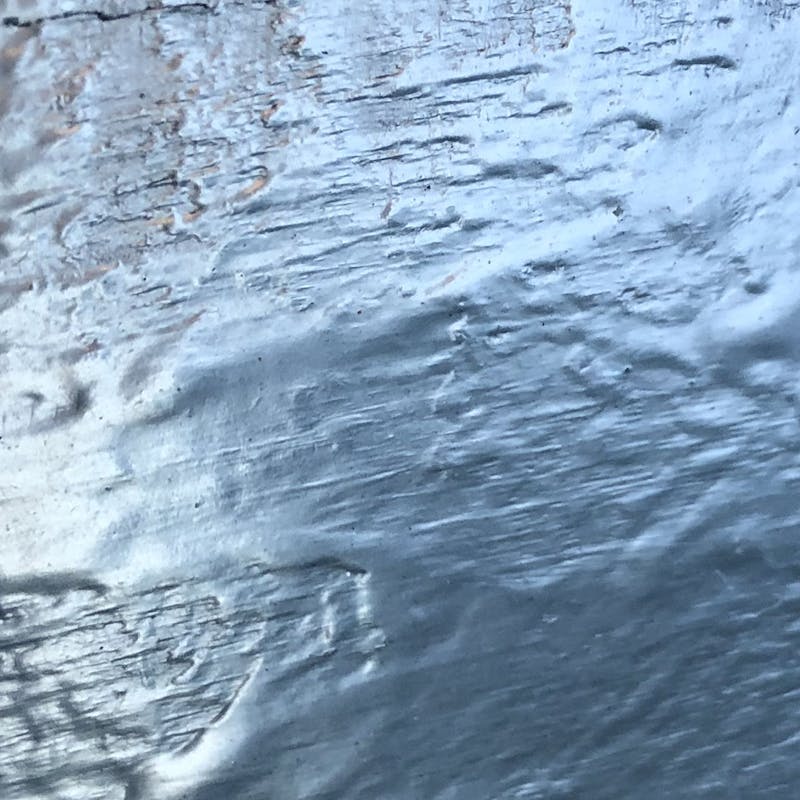

Picture Framing

Not as common an issue now however one that occasionally crops up. All of our emulsions can be used to cut in around the edge of a wall prior to roller application of the main surface. Picture framing with Tikkurila materials occurs when the film build of the paint applied around the edges is higher than the roller applied mid section. Due to the solids content of most Tikkurila materials it is quite easy to apply a relatively high loading/ film build using a brush. If this film build is not reduced using a couple of brush sweeps then the edge between the border section applied by brush and the center section applied by roller will be evident. This joint between differing film builds will be more noticeable when using higher sheen products like Optiva 20 and Luja 40, it will also be exacerbated by deep colours with high colourant contents where the shape/ texture difference between the brushed section and rollered will be more noticeable.

The issue can be easily avoided if the applicator is just mindful of not leaving a very heavy border and working the product around the borders of walls to ensure no defined film edge is left. Tikkurila products can be recoated after a wet edge had disappeared without issue providing the film build a the joint between border and roller section is low enough not to be caught by light.

Issue: Picture framing / bordering

Cause: High film build on edge sections

Solution: Ensure film build is not too high on borders, no visible / distinct edge is left

Internal trim paint not covering (WB Acrylic)

Tikkurila have three fully water based options; Helmi, Everal Aqua and Intact. Helmi is a water based acrylic where as Everal Aqua and Intact are both water based enamels. Each product applies slightly differently to the other allowing the applicator to find a product which best suits their technique. Helmi is very unique in its application properties, you can apply a very high film build (way beyond what most applicators in the UK are used to) and in order for the product to work correctly a high film build must be applied. If after first coating it appears that the Helmi film is not solid then try applying a heavier second coat. Helmi and similar products rely heavily on surface flow and their self levelling ability. If too little product is applied to the substrate then the product will not level properly and the dried film will appear patchy. It does seem very obvious but the application properties of the Tikkurila WB acrylic systems are very, very different, as such a change of technique is required.

Issue: Grinning, low hiding

Cause: Low film build

Solution: Ensure WB acrylic is applied liberally. Product should appear to flow and self level, do not over work the paint film to remove brush marks. Trust that the product will self level and not sag.

Pinholes in WB Arylic film when spraying

Pinholes tend to appear when too low a film build is applied to the substrate. If the spray film is too low due to lack of pressure, wrong tip selection or over thinning then the atomised product does not flow correctly over the substrate and gaps appear (pinholes). Pinholes are most common when applying black and white as visually it is very difficult to distinguish between a first coat and second. When using these colours the natural propensity is to apply a lower film build by sweeping over the surface faster in order to avoid runs and sags. Pinholes very rarely occur when first coating over primer as the shade differentiation is such that the sprayer can easily see the volume of paint being applied and is more confident that the film is as it should be.

Issue: Pinholes in sprayed film

Cause: Low film build

Solution: Apply more product. This can be achieved as follows:

- Adjust pressure

- Change tip size

- Slow down sweep over substrate

Blistering in newly applied WB paint film

Blistering is quite common and can be caused by a number of factors:

- High temperature of substrate, air or painting in direct sunlight

- Reaction between substrate and new paint film (cissing)

- Loss of adhesion between coats

- Excessive moisture content in the substrate

- Resin or Resin gasses

- Direct moisture ingress from an architectural defect

The most common three causes are covered in more detail below:

Blistering during high temperatures

This normally happens when using WB materials internally on walls or WB materials externally on doors and substrates with larger surface areas. The cause is the rapid drying of the first few microns of the surface paint film due to the temperature. This drying forms a solid paint film at the surface which prevents the moisture vapour evaporating from the wet product below escaping. The trapped water vapour causes a blister to form. This process can happen internally (walls/ woodwork) or externally, cladding, weatherboard, doors soffit facia.

Prevention is the best cure, if the substrate or atmosphere surrounding the surface to be painted is too hot then reduce the termperature of it (don’t paint in direct sunlight) wait for the shade etc. or if internal rooms are very warm open windows, insert a fan and ensure good movement of air. Slowing the drying process is the solution.

Cissing/ Reaction between substrate and new film

Reactions happen, the best way to avoid any possible reaction is to ensure all surfaces are thoroughly clean and stable. If chemical contamination is left on surfaces there is a probability localised cissing will occur, an example would be localised cissing blistering on a kitchen in an area where oil or contamination was left.

Another cause of blistering due to chemical reaction is when Latex based products (not just Tikkurila) are applied over emulsion surfaces with very high vinyl contents. This is common when applying emulsions over “mist coated” surfaces where vinyl based products have been used as the high dilution rate effectively leaves a very concentrated level of vinyl on the surface which can react with the latex based finishing coats.

In order to prevent cissing or blistering it is essential all surfaces to be painted are cleaned with appropriate cleaning agents that are suitable for the surface and its potential contamination. In order to avoid any potential vinyl reaction if it is possible that the scenario above has occurred use the appropriate primer (Optiva Primer as the first coat)

Adhesion loss between coats

Generally caused by lack or wrong primer and or insufficient preparation. Blisters can occur during the curing process as the newly applied film tightens and is not able to bond correctly to the existing surface whether that is painted or unpainted. During the curing process it is also possible to have blisters form even when the new paint film adheres to the existing if the bond between the old film and the surface underneath is poor.

In order to avoid blistering due to inter-coat adhesion failure preparation is critical. Ensure all surfaces are washed and free from contamination, remove unstable paint with sandpaper and use appropriate primers. It needs to be stated that if the existing paint film looks stable and well adhered but a blister forms after application of the new coating and that blister is back to bare timber or the coating before the existing it is the case that the previous coatings are not adhered and the application of a new paint film with its film tension has caused the blister.

Softening of the paint film / no or slow curing

Fully water based products dry quickly but cure slowly so it is essential that notice is taken of the CURING times for each individual product.

If films remain soft after the detailed curing time it is normally due to one of the following reasons:

- Excessive moisture or other chemical compound has been introduced to the paint film/ system before it has fully cured. Most commonly reported softening incidents are down to excessive steam in kitchens (cooker hoods) or bathrooms due to cooking or showering. You can cook and shower when the films are curing but a sensible view must be taken if the room becomes saturated with steam then an adverse effect is probable. The second most common occurrence is washing or wiping the paint system before it is fully cured. in general terms we recommend leaving any new system around 4 weeks before heavy washing.

- Contamination of the surface by aggressive solvents or hydrocarbons. Some contaminants are very hard to remove from surfaces prior to painting. We have found petrol, diesel, acids and ingrained oils on surfaces tested for system failure. If aggressive solvents and compounds are left on the surfaces then it is very likely WB systems will not cure.

The simple fix for both scenarios is ensure curing times are adhered to and treat new paint films gently initially. When it comes to chemical contamination the paint film will require scraping back, substrate fully cleaned, prior to priming and painting.